Pure Water Southern California – Our Water. Our Future.

Find a Document

In our climate, water is too precious to use just once. That’s why Metropolitan is partnering with the Los Angeles County Sanitation Districts on Pure Water Southern California, a regional water recycling program that would purify and reuse cleaned wastewater that currently flows into the ocean. At full scale, Pure Water Southern California would produce 150 million gallons of purified water each day.

By delivering a new, climate-resilient supply of locally available water, Pure Water Southern California would benefit the 19 million people living within Metropolitan’s service area. It also would become one of the world’s largest water recycling programs.

About the

Grace F. Napolitano

Pure Water

Southern California

Innovation Center

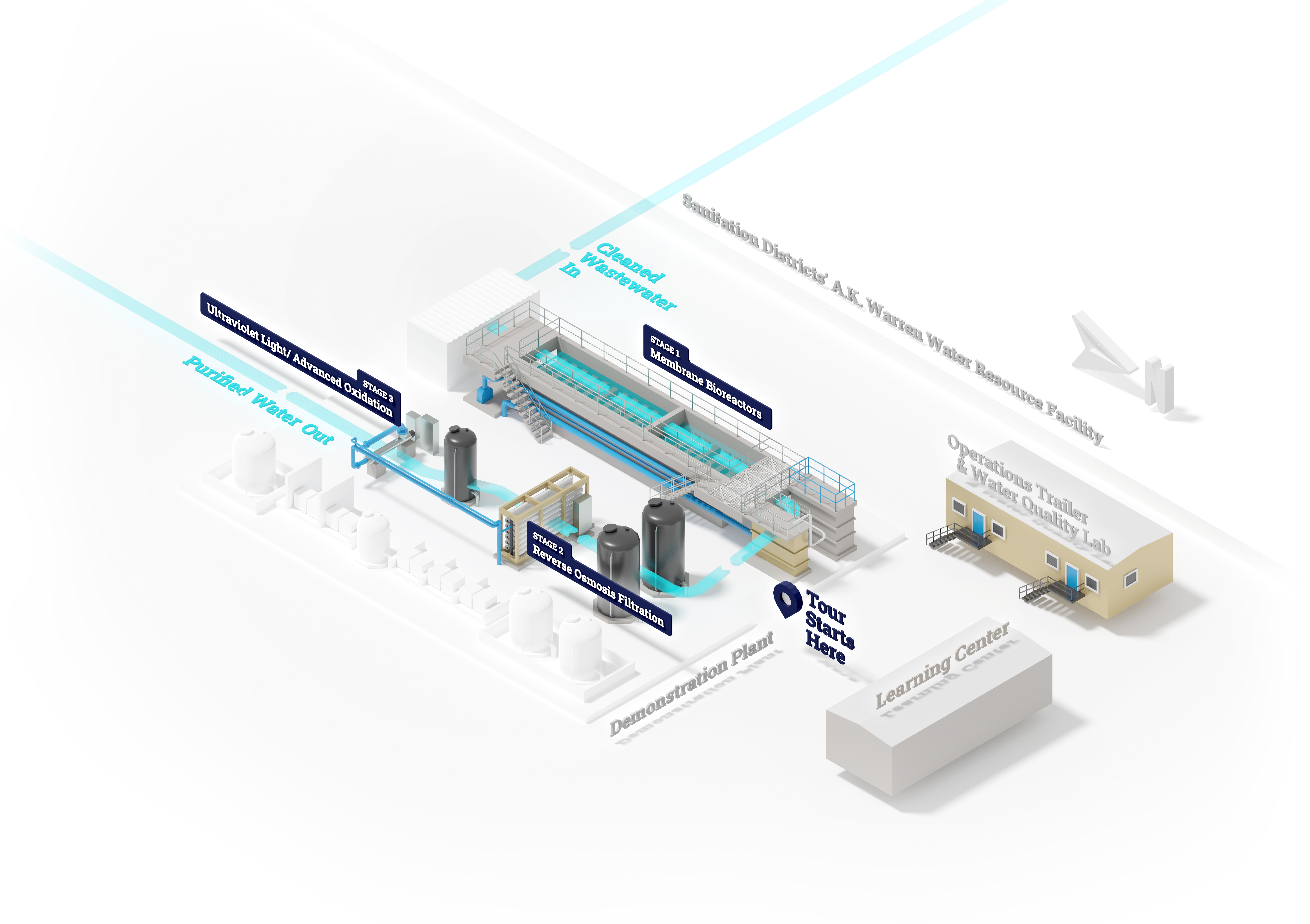

Think of it as a living laboratory. The Grace F. Napolitano Pure Water Southern California Innovation Center features a state-of-the-art demonstration plant, which began operation in October 2019. One of the main purposes of the demonstration plant, which produces 500,000 gallons of purified water per day, is to facilitate regulatory approval of the innovative purification technology being proposed for the full-scale program. The demonstration plant also is generating information that will enable optimal design of the program’s advanced water purification facility.

Here, scientists and engineers test each stage of the purification process to make certain that the purified water meets or exceeds California’s water quality standards, which are among the highest in the world. This means the purified water is safe to use for the replenishment of local groundwater basins and eventually for drinking.

Once the program is fully operational, purified water would be transported up to 60 miles through a network of pipelines to groundwater basins, industrial facilities and potentially to two of Metropolitan’s water treatment plants.

A Look Inside How It Works

The demonstration plant uses an innovative three-step purification process. The first step involves membrane bioreactors; the second step is reverse osmosis; and the third step is ultraviolet disinfection and advanced oxidation.

What makes our purification process innovative is how and when MBRs are used. They have been used in the wastewater industry for decades but are relatively new for purifying water for reuse. Initial pilot studies by Metropolitan and the Sanitation Districts found that MBRs may be a cost-effective first step in the purification process for water reuse. Once approved by state regulators using data from our demonstration plant, this innovative technology could be applied across California and even globally to increase the efficiency of other water recycling programs.

The Purification Process

Membrane Bioreactors

Membrane bioreactors use biological processes and membrane filters to clean water.

Air is added to biological process tanks to create an environment where helpful microorganisms can thrive. These microorganisms effectively remove organic material and nitrogen compounds, such as ammonia and nitrate, from the water.

The water also flows through tanks where thousands of straw-shaped membranes with tiny openings filter and remove microscopic materials, including microorganisms and other particles. Many of the microorganisms and particles removed through this process are smaller than 1/100 of a grain of sand.

Reverse Osmosis

Reverse osmosis is often considered the core step in the water purification process, as it effectively eliminates more than 99% of all impurities. Water leaving the MBRs is pressurized through a series of pumps and pushed through tightly wound membranes. RO membranes selectively allow water molecules to pass through, while blocking the passage of microscopic materials such as bacteria, pharmaceuticals and salts.

Reverse osmosis is commonly used to remove salt in desalination projects, as well as in the commercial production of bottled water.

Ultraviolet Light/Advanced Oxidation

Ultraviolet light is a powerful disinfectant used to inactivate viruses in water. When UV light is combined with a strong oxidant such as hydrogen peroxide or sodium hypochlorite, extremely reactive molecules are created. These molecules effectively remove any trace chemical compounds that may persist through the first two phases of water purification. The combination of the UV light and a strong oxidant is referred to as the Advanced Oxidation Process. This is a final refining step that ensures the purified water is safe and meets or exceeds all water quality standards.

Demonstration Plant Tours

Take a tour of the Grace F. Napolitano Pure Water Southern California Innovation Center to learn more about the demonstration plant, its innovative purification process and the importance of water recycling to Southern California’s future water supply. In-person tours are available in English and Spanish. Virtual tour options are also available.

“The best science tells us that we need to act now to adapt to California’s water future.”

Gov. Gavin Newsom

Over a Decade

in the Making

Since the early 1960s, the Los Angeles County Sanitation Districts have operated water recycling plants that clean and reuse wastewater to safely replenish groundwater basins, our natural underground water reservoirs. Since the early 1980s, Metropolitan has supported the development of new local supply projects by its member agencies, including recycling projects. Until now, Metropolitan has never had a water recycling project of its own, but through this creative partnership, the two agencies are collaborating on what could set a global precedent as one of the largest water recycling programs.

This large-scale program requires many collaborators, and Pure Water Southern California has many partners, including groundwater basin managers, other Metropolitan member agencies and even water agencies in Arizona and Nevada. The shared goal is to create a sustainable water future that balances local water resources with imported supplies from the Colorado River and the State Water Project, which are experiencing increased stress and long-term uncertainty in the midst of a changing climate.

Innovation at Work

Pure Water Southern California is novel in its proposed purification process and in its regional scale, but the concept of recycling water is not new and has been widely recognized as proven technology. Several countries worldwide and many communities across Southern California, including some in Los Angeles, Orange and San Bernardino counties, use recycled water to replenish groundwater basins that eventually supply water for drinking and other applications.

Click on the

The City of San Diego is constructing a new water recycling plant and associated facilities to produce 30 million gallons of purified water daily. This is the first phase in its multi-year Pure Water Program that will provide one-third of the City’s water supply by 2035.

The Edward C. Little Water Recycling Facility purifies water from the City of Los Angeles' Hyperion Wastewater Treatment Plant and produces water for irrigation water, industrial use, and adding to groundwater to prevent seawater intrusion.

The Groundwater Replenishment System is the world's largest advanced water purification system. The system produces 100 million gallons of purified water daily to help refill groundwater basins. It is currently undergoing an expansion to 130 million gallons daily.

The Albert Robles Center purifies and recycles approximately 14.8 million gallons of water daily, which is used for groundwater replenishment. The Center is a multipurpose and multi-benefit site which includes an Advanced Water Treatment Facility, a fully digital Learning Center, and a water-efficient Demonstration Garden.

Pure Water Oceanside is an advanced water purification program that purifies recycled water to create a new, local source of drinking water. Between 3 to 5 million gallons of drinking water is created each day, enough to provide 32% of the City of Oceanside’s water supply.

Recycled water makes up more than one-third of Eastern Municipal Water District’s water supply portfolio. Recycled water is used for agriculture, irrigation and industrial use. EMWD is also planning to produce purified recycled water for groundwater replenishment through its Purified Water Replenishment program.

The City of Oxnard’s Advanced Water Purification Facility produces recycled water for irrigation of parks, medians, golf courses and athletic fields; watering of agriculture crops; and process water for local industries. The City plans to expand its facility and use recycled water for groundwater replenishment.

IEUA receives and cleans more than 50 million gallons per day of wastewater, which is then used for agriculture, municipal irrigation, industrial uses, and for groundwater replenishment. IEUA is also planning to provide additional purified recycled water for groundwater replenishment by 2028.

The East County Advanced Water Purification Program will create a new drinking water supply utilizing state-of-the-art technology to recycle the region’s wastewater. The project is under construction and scheduled to be online in 2025.

The Los Angeles County Sanitation Districts began replenishing groundwater with recycled water in 1962 at their Whittier Narrows Water Reclamation Plant. Recycling has since expanded to 10 treatment plants and they have recycled over 1 trillion gallons.

Pure Water Southern California’s Environmental Review Process

Steps in the Environmental Review Process

In compliance with the California Environmental Quality Act, Metropolitan is conducting an environmental review of the Pure Water Southern California program. The environmental review process encourages public participation and input, and it informs Metropolitan, the Los Angeles County Sanitation Districts, and the community of the program’s potential environmental impacts, proposed mitigation measures, and program alternatives. The environmental review for the program is now in its final stages, with the Final Environmental Impact Report anticipated for completion in early 2026.

1. Scoping Phase: Complete

The first part of the environmental review process is the scoping phase, which is initiated by a Notice of Preparation that tells public agencies and interested parties that a Draft Environmental Impact Report will be prepared. Feedback is encouraged to help identify environmental issues and raise questions and concerns for further study in the Draft EIR. Potential environmental impacts, mitigation measures, and program alternatives also are considered.

The scoping phase was completed in November 2022.

2. Draft EIR: Complete

The Draft EIR informs the public and decision-makers about a project’s potential environmental impacts from the program’s construction and long-term operation and identifies ways to avoid, minimize or reduce those impacts.

The public can review the Draft EIR and provide comments about the adequacy of the environmental analysis, including the identification of potential environmental impacts, proposed mitigation measures and program alternatives. Officially submitted comments will be reviewed by Metropolitan and addressed in the Final EIR.

The public review period for the Draft EIR ended on July 14, 2025.

3. Final EIR Certification: Early 2026

After reviewing and preparing responses to public comments provided during the DEIR stage, Metropolitan staff will finalize the EIR, which will be considered for certification by Metropolitan’s Board of Directors at a public board meeting.

SB 149 - Record of Proceeding

The California Environmental Quality Act record of proceeding, also called the administrative record, for Pure Water Southern California is provided here. Metropolitan is making the record available consistent with Senate Bill 149. The record is organized consistent with the 2025 California Rules of Court. If you have any difficulty accessing records in the CEQA record of proceeding, please contact [email protected].

Resources

English

Pure Water Southern California Program Brochure

A Look Inside: The Grace F. Napolitano Pure Water Southern California Innovation Center

Benefits of the Pure Water Southern California Program

Spanish

Folleto del programa Pure Water Southern California

Un Vistazo Al Interior: El Centro de Innovación Grace F. Napolitano Pure Water Southern California

Presentations

Pure Water Southern California Partnership Development Update - Presentation (November 2024)

Pure Water Southern California Quarterly Update - Presentation (September 2024)

Update on Outreach for Pure Water Southern California - Presentation (August 2024)

Update on Public Opinion Research for Pure Water Southern California - Presentation (August 2024)

Pure Water Southern California Quarterly Update - Presentation (June 2024)

Update on Pure Water Southern California Partner Agreements - Presentation (June 2024)

Review of Cost Recovery Alternative 6 - Presentation (March 2024)

Pure Water Southern California Quarterly Update - Presentation (March 2024)

Pure Water Southern California Demand Projections - Presentation (March 2024)

Review of Cost Recovery Alternative 6 - Presentation (March 2024)

Assessment of Reuse Alternatives for Pure Water Southern California - Presentation (January 2024)

MWD Board Item 3-B Staff Presentation (November 2023)

MWD Board Item 6-A Staff Presentation (October 2023)

MWD Board Item 3-A Staff Presentation (June 2023)

MWD Board Item 3-B Staff Presentation (June 2023)

MWD Board Item 3-B Staff Presentation (March 2023)

MWD Board Item 7-3 Staff Presentation (March 2023)

MWD Board Item 7-5 Staff Presentation (January 2023)

Technical Resources

Click here to access technical studies, white papers and letters of intent and agreements for the Pure Water program.

Awards & Recognitions

Contact